-

Semiconductor Lithography Optics (Photolithography) in Hydrogen

Today’s semiconductor manufacturing uses Photolithography in the microfabrication process to pattern parts of a thin film or the bulk of a substrate. It uses extreme ultra violet light to transfer complex geometric patterns from a photomask to a light-sensitive chemical “photoresist” on the substrate. A series of chemical treatments then either engraves the exposure pattern into,…

-

Hydrogen Production Certification

Suppliers of high purity hydrogen generally provide a certificate of analysis (CoA) with each shipment. A CoA will typically call out several impurities, eg. O2, H2O, N2, CO, CO2, CH4 , etc . As most analytical instruments can only detect a few of the required impurities, the gas producer or distributor will need to invest…

-

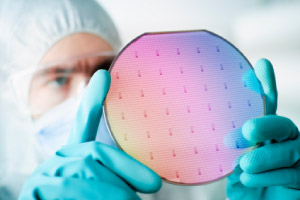

Polysilicon Manufacturing

Hydrogen is used in the production of polysilicon manufactured in fluidized bed reactors (FBR) from silane (SiH4) gas. In order to meet the purity requirements of the solar industry, polysilicon manufacturers must use ultra-pure starting materials including Hydrogen. Power+Energy HEMS analyzers detect all impurities up to 100 Atomic Mass Units (AMU) with part-per-billion (ppb) levels…

-

SAE J2719 Hydrogen Analyzer

The Society of Automotive Engineers (SAE) has developed a specification for hydrogen intended for use in a PEM fuel cell in a motor vehicle, SAE J2719. This same specification has been adopted internationally by the International Standards Organization (ISO). Importantly the specification sets upper limits for the critical impurities of sulphur and carbon monoxide. These…

-

Power Semiconductor Device Manufacturing

High-purity Hydrogen is used as a carrier gas to transport metal organic source chemicals into the MOCVD reaction chamber. Power devices are either Gallium Nitride (GaN) or Silicon Carbide (SiC) devices. The performance of GaN devices vary depending on the quantity of oxygen contained in the device structure. Nitrogen is a dopant in SiC devices. Controlling…

-

Pure Hydrogen in TFT LCD Manufacturing

Similar to other thin-film manufacturing processes, pure hydrogen is used in combination with silane and with dopant gases in the production of thin-film-transistor liquid crystal display (TFT LCD) panels. Consistent control of impurities is required to ensure the high yields needed for a profitable TFT LCD production operation. Power+Energy HEMS analyzers detect all impurities up…

-

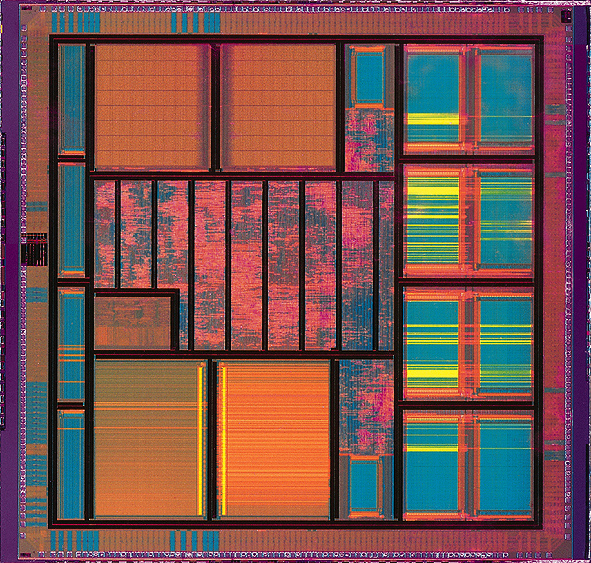

Semiconductor Processing Hydrogen

Hydrogen features in a number of sensitive semiconductor processes where the control of impurities into the sub part-per-billion (ppb) range has a critical impact on device function or yield. Power+Energy suggest using HEMS™ instruments to verify hydrogen purity prior to its introduction into key processing steps. Unlike other analysis method, our Hydrogen Elimination Measurement System…

-

Photovoltaic Manufacturing

Hydrogen is used in combination with silane to produce amorphous and micro-crystaline silicon layers during the thin film silicon photovoltaic manufacturing process. The electrical output of the resulting solar cell, its efficiency and its lifetime are all affected by the concentration of nitrogen and oxygen atoms contained within the device structure. Control of these impurities…

-

High Brightness LED Manufacturing

Hydrogen is used as a carrier gas to transport metal organic source chemicals into the MOCVD reaction chamber. High Brightness LEDs are typically Gallium Nitride (GaN) devices. The performance of a GaN device can vary depending on the oxygen impurity levels in the device structure with higher levels of oxygen lowering intensity and shifting wavelength.…